News

Enhancing Resilience in Global Supply Networks

07/05/2024

Understanding the Dynamic Landscape of Global Supply Chains

Global supply chains have long been integral to international business, serving as a catalyst for global development and reshaping industries. Since the 1960s, companies have sought after cost-effective and skilled suppliers overseas, a practice known as global outsourcing. Initially centered on simple assembly, supply chains have evolved into "buyer-driven" networks, spanning from regional production-sharing to comprehensive global setups. This evolution reflects the dynamic nature of international competition and has spurred continuous economic growth worldwide.

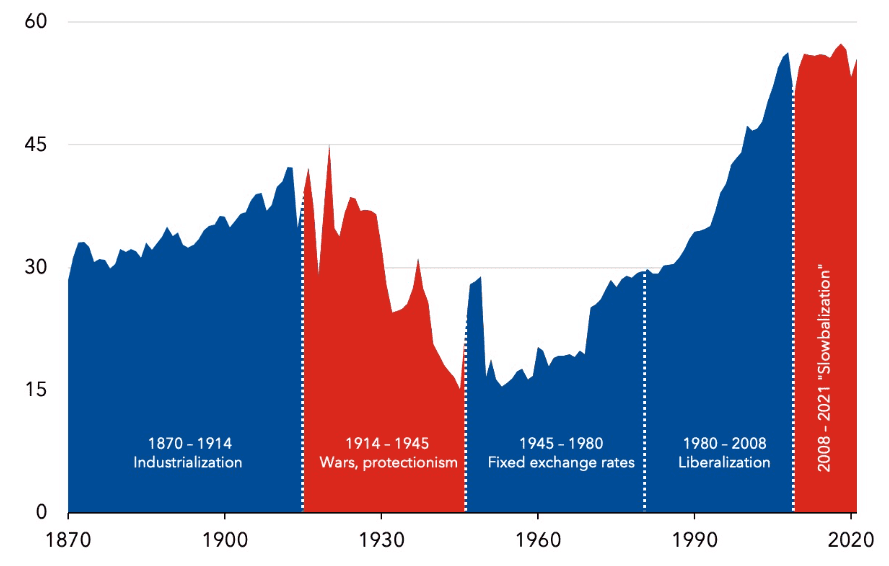

Figure 1 Trend in Global Economic Growth: Sum of Exports and Imports in Percent of GDP

However, despite its longstanding progress, recent years have seen a slowdown in global trade, a phenomenon termed "slowbalisation," accompanied by a political pushback against globalization. Data indicates that globalization has plateaued since the 2008 global financial crisis, attributed to waning political support amid increasing geopolitical tensions. This shift is exemplified by Nikolaus Lang, a BCG managing director, who observes a new dynamic emerging, characterized by a US and EU-led community facing off against a China-Russia counterpart, alongside the potential emergence of a third grouping of non-aligned nations. Furthermore, the lingering effects of recent Covid-19 supply/demand shocks are evident in the persistent imbalance between supply and demand for essential goods, leading to sustained increases in both producer and consumer prices.

As a result, a trend towards deglobalization is emerging, prompting a re-evaluation of supply chain strategies. Policy proposals are primarily focusing on either a) shortening/domesticating global supply chains through reshoring activities or b) diversifying them. For example, the United States is actively incentivizing reshoring efforts, particularly in manufacturing sectors that have historically relied heavily on China.

Despite these shifts, certain aspects remain constant. Consumer demand for low prices, particularly during economic downturns, will persist, and firms won't be able to inflate product/service prices solely due to domestic manufacturing costs. Competitive pressures will enforce this. Additionally, the need for efficiency and prudent use of resources will endure. It is thus arguably imperative for companies to prioritize bolstering the resilience of their global supply chains while maintaining competitiveness, rather than hastily abandoning these established systems in favor of alternative strategies.

Resilience in Global Supply Chains

Resilience is often praised across various sectors as a vital asset during challenging times. For instance, in healthcare, resilience denotes the ability to manage stress effectively, achieving goals with minimal psychological and physical strain. It is akin to a 'bounce-back' effect, ensuring quality care, compassionate support, and the endurance of healthcare professionals.

Over a decade ago, supply chain management embraced the concept of resilience, gaining valuable insights into its drivers and effectiveness. While there is no universally agreed-upon definition, resilience in supply chain management often emphasizes systemic attributes, considering the broader network of organizations involved rather than individual entities. This approach allows for the examination and optimization of the entire supply chain system, as its components are modifiable and amenable to redesign. Ultimately, the objective is to enhance control over the entire end-to-end system, ensuring its robustness and adaptability to various challenges.

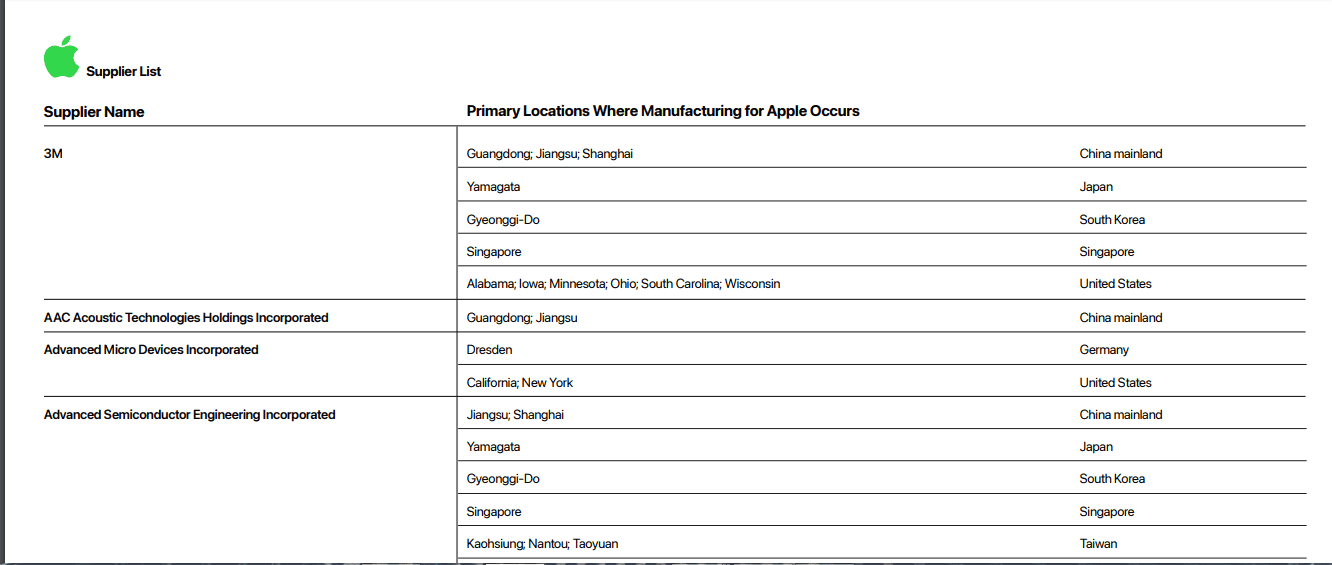

This very concept – resilience – holds immense significance for all types of supply chain systems, and more so global ones, crucial for designing and managing effective value creation networks. For instance, companies like Tesla implement diversified supplier approaches, relying on approximately 800 suppliers to source 2,000 parts for a single model, such as the S Model. Similarly, Apple discloses its list of 200 suppliers while retail giants like Walmart collaborate with over 100,000 providers globally, along with carriers and intermediaries. Through deliberate supplier diversification, these firms mitigate risks such as single-supplier dependency problems and market fluctuations including pricing changes and availability issues, consequently ensuring resilient and agile supply chains capable of persisting, adapting, or transforming amidst disruptions, like the failure of a single supplier to deliver required materials.

Figure 2 Sectional Snippet of Apple's Suppliers List

Improving Resilience in Global Supply Chains: Enhancing Visibility

While supplier diversification surfaces as a vital strategy for enhancing supply chain resilience, its application without comprehensive visibility across the entire supply chain becomes challenging, particularly in effectively selecting or optimally choosing between the multiple sources, not forgetting the needed management of delivery points and logistics. Supply chain visibility, recognized as a crucial competency for resilient supply chains, facilitates planning, monitoring, and control decision-making by utilizing relevant real-time data and consequently enables the creation of a digital twin or a virtual representation of the supply chain. This empowers organizations to proactively manage their operations or rather take control or hold mastery over their environments, moving away from reactive approaches. With increased agility, they can effectively address fluctuations in demand and disruptions in transportation, ensuring profitability and customer satisfaction.

Yet, one of the toughest hurdles in supply chain management is the absence of comprehensive end-to-end supply chain visibility. Many businesses today find it difficult to monitor the flow of products, materials, and information throughout their supply chain networks, hindering accurate forecasting among other problems. Exacerbating this challenge is the complex nature of global supply chains, many of which, if not all, involve multiple third parties at different stages. As a result, manufacturers struggle to maintain control and oversight of goods, whether upstream, downstream, or in transit. A survey conducted by SupplyChainWorldwide found that approximately 70% of companies considered their supply chains to be “very” or “extremely” complex. This complexity often results in a lack of visibility and accurate monitoring of various events, causing disruptions in supply chain activities. Other surveys by the Business Continuity Institute reveal that over 85% of firms fail to monitor disruptions beyond tier three, with nearly 33% not analysing their supply chain to identify the original source of disruption. Further, a recent KPMG survey within the apparel industry revealed that only 19% of respondents claimed to have full visibility of all stakeholders across their entire supply chain, while just 15% had complete traceability of the materials used in their products.

Figure 3 Global Supply Chains as A Link of a Interconnected System

Such insights highlight weaknesses in the end-to-end visibility needed for global supply chains, emphasizing the importance of not hastily abandoning these longstanding systems in favour of deglobalization or other strategies. It becomes crucial to address the complexity of these chains to improve visibility and enhance efficiency.

Harnessing Technology to Improve Visibility

Admittedly, the integration of technology to bolster supply chain visibility seems like a well-explored topic, and indeed quite a prevalent subject in academic literature and industry discussions. Yet, at the risk of sounding cliché in addressing this subject, a cursory online search using keywords like 'poor technology adoption' and 'supply chain management' yields numerous recent articles addressing this issue. For instance, a piece by SupplyChainBrain delves into the persistent barriers hindering widespread adoption of beneficial technologies, such as artificial intelligence (AI), among supply chain executives. These barriers are listed to include cost implications, potential disruptions, and a lack of expertise. Consequently, failing to adopt these technologies leads to missed opportunities that enhance supply chain visibility, particularly within the transportation and logistics sector. This underscores the ongoing importance of addressing the need for adoption for these technologies and their suitability in alleviating end-to-end supply chain visibility challenges.

So yes, utilizing cutting-edge technology to strengthen supply chain systems is crucial, especially in the context of the rapidly expanding global ecommerce landscape. Advancements such as AI and machine learning hold immense potential to foster flexibility and transparency within supply chains, aiding manufacturers in navigating volatility. Forward-looking retailers are already leveraging these technologies to great effect.

Notably, AI has proven particularly transformative in inventory management, achieving significant cost reductions. Studies have shown that AI-driven inventory control can lead to a remarkable 20% decrease in inventory carrying costs and a 50% reduction in stockouts. By utilising sophisticated algorithms and data analytics, AI/ML technologies significantly improve demand forecasting accuracy. They achieve this by analysing real-time data and providing insights into inventory levels, allowing companies to predict market trends and customer preferences more accurately. This predictive capability enables efficient inventory management, minimizing excess stock and reducing stockouts, thus optimizing working capital. Moreover, AI/ML algorithms optimize logistics, leading to streamlined transportation networks and cost reductions.

At the forefront of these advancements too are Digital Twins, virtual representations of supply chains that utilize real-time data for accurate tracking of goods and predictive analytics to optimize operations. With Digital Twins, organizations gain instant visibility into their inventory status, eliminating the need for multi-day updates. For manufacturers, Digital Twins enhance efficiency by providing real-time inventory insights, facilitating decision-making adjustments, and exploring alternative transportation models. They also enable direct shipment to consumers, bypassing traditional warehouse-to-store routes. Digital Twins analyse various scenarios and detect both external and internal system changes, offering alternative solutions. Overall, Digital Twins revolutionize supply chain management, offering unprecedented visibility and agility in decision-making processes.

However, haphazardly adopting available technologies is unlikely to yield results. Effective supply chain visibility management necessitates understanding the factors that influence it and prioritizing them accordingly. One crucial factor is information sharing, tightly linked with supply chain integration. This correlation has been extensively studied, highlighting the role of information sharing in enhancing supply chain performance and remaining competitive. Sharing information allows supplier network members to attain the necessary visibility to respond to evolving business conditions. As such, the level of visibility directly influences performance improvements within the supply chain, making prioritizing information sharing a strategic imperative for organizations striving to excel in the marketplace.

However, despite this recognition, global supply networks in various industries still grapple with inaccurate and delayed information sharing. Many businesses hesitate to share data with partners due to concerns about data security, privacy, and inadequate tracking capabilities. Trust and confidentiality also play significant roles in this reluctance. Fears include data leaks to competitors, misuse, price hikes, exploitation, supplier changes, or unfair terms imposition.

While acknowledging these as genuine concerns, the advantages of data sharing surpass the risks, necessitating a focus on proper implementation. Dispelling misconceptions, such as the belief that data sharing entails divulging all information, is crucial. Partners should understand they can selectively share relevant data while retaining control over sensitive information. Importantly too, building trust and mutual benefits through transparent communication, contractual agreements, incentives, and feedback mechanisms is vital. Respecting each other's confidentiality and intellectual property rights enhances collaboration and ensures equitable partnerships in the supply chain. To that end, effective information sharing should be supported by robust policies and strategies throughout supply chain operations with these frameworks serving as foundational pillars for integration within the supply chain network.

In conclusion, stakeholders must re-evaluate their approaches to global supply chain management and avoid prematurely abandoning established systems in favour of new strategies. The evidence demonstrates the effectiveness and efficiency of global supply networks, but there remains considerable room for improvement. Evidence has highlighted that only a few companies benefit from the visibility and advantages associated with effective supply chain management. Many industry players cite the complexity of supply chain networks as a significant hurdle to achieving efficiency and effectiveness in their global supply chain endeavours, particularly in relation to supply chain visibility.

Furthermore, research indicates that despite having access to the necessary technological advancements to facilitate supply chain visibility, many businesses across various industries still struggle with delayed and inaccurate information sharing. This is partly due to concerns about data security and privacy, among other issues, which have made companies hesitant to share data with their partners.

In view of these challenges, it is clear that many of these issues have viable solutions. However, these solutions have not been fully explored or implemented, making it premature to dismiss global supply chains as unviable.

Capire le complessità descritte nell’articolo di cui sopra e saper affrontare le sfide delle Supply Chain globali, sono aspetti quindi cruciali per i professionisti e Leader dell’area Supply Chain Management. Per rimanere al passo, è essenziale investire in una formazione state-of-the-art.

I nostri programmi APICS, tra i quali CSCP (Certified Supply Chain Professional) e CTSC (Certified in Transformation for Supply Chain), sono progettati per fornirti preziose conoscenze e best practice per la gestione e trasformazione di supply chain locali, regionali o globali: confrontandoti con i nostri istruttori, esperti del settore con pluriennale esperienza in Operations e Supply Chain Management presso aziende strutturate e multinazionali, apprenderai aspetti essenziali come progettazione della supply chain, ottimizzazione, end-to-end connectivity, visibility e metriche.

Inoltre, al termine dei percorsi e al superamento degli esami, otterrai certificazioni riconosciute a livello globale, che metteranno in luce la tua conoscenza ed esperienza.

Contatta Jessica Mariotti per informazioni sui nostri corsi open e in-house in Italia e Svizzera, sulle fee agevolate per early registration e per iscrizioni. Email j.mariotti@advanceschool.org – numeri di telefono sotto contacts

Corsi collegati

-

Master APICS CSCP - Certified Supply Chain Professional - Interactive Live Webinar

Il Master CSCP in modalità live webinar è finalizzato a preparare il candidato alla certificazione internazionale Certified Supply Chain Professional (CSCP) di APICS, specifica per l'area Supply Chain Management. » -

Master APICS CTSC - Certified in Transformation for Supply Chain

Questo programma è volto a preparare i candidati per la certificazione internazionale APICS CTSC (Certified in Trasformation for Supply Chain) »